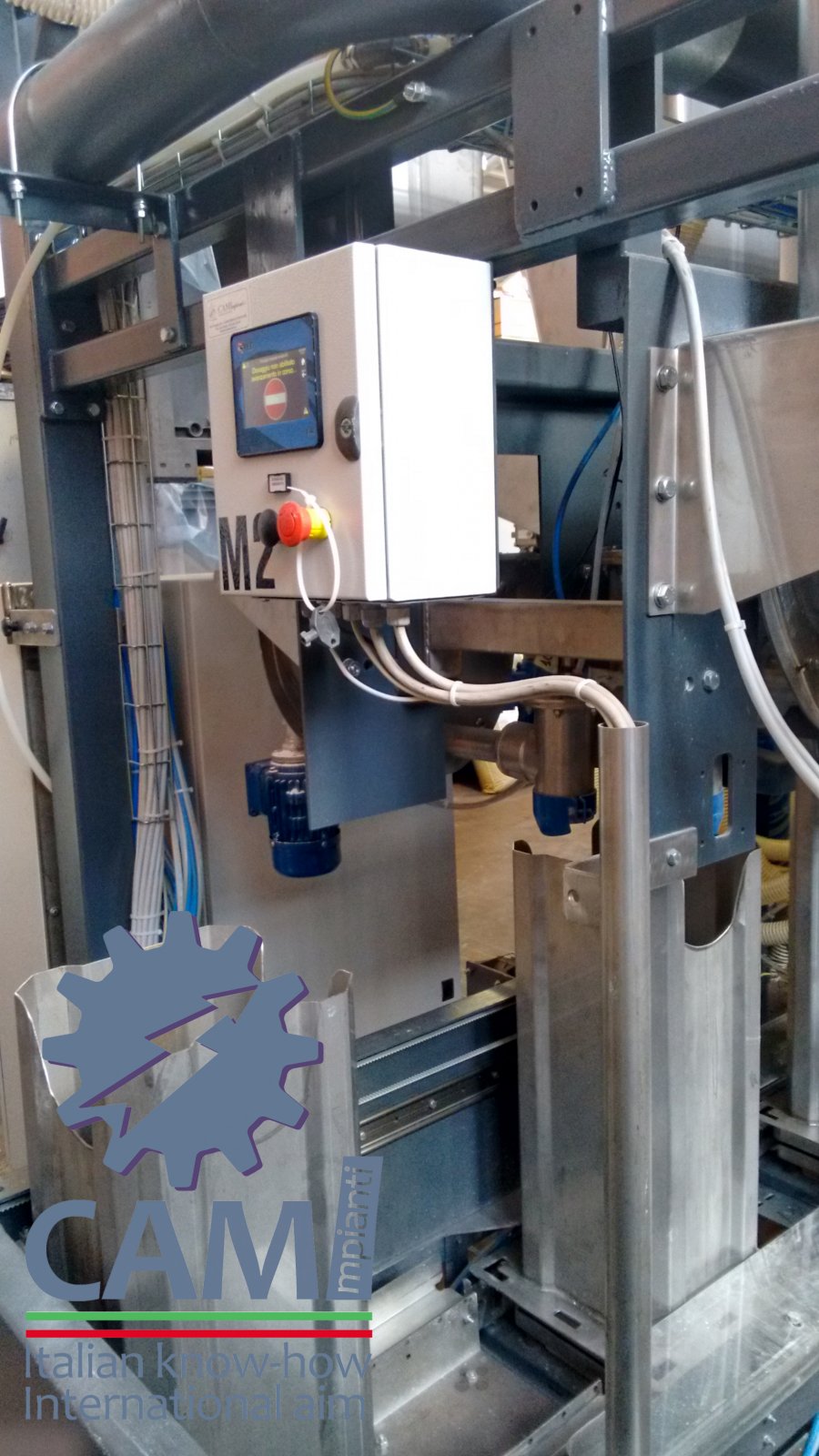

Automatic Batch Composer | micro dosing system

ABC

ABC system is CAMImpianti’s answer to the problem of adding micro batches to main components, both in the food and chemical and rubber field. Just this latter sector has increasingly developed owing to the variety of the compponents and dosing set points.

The ABC main features are:

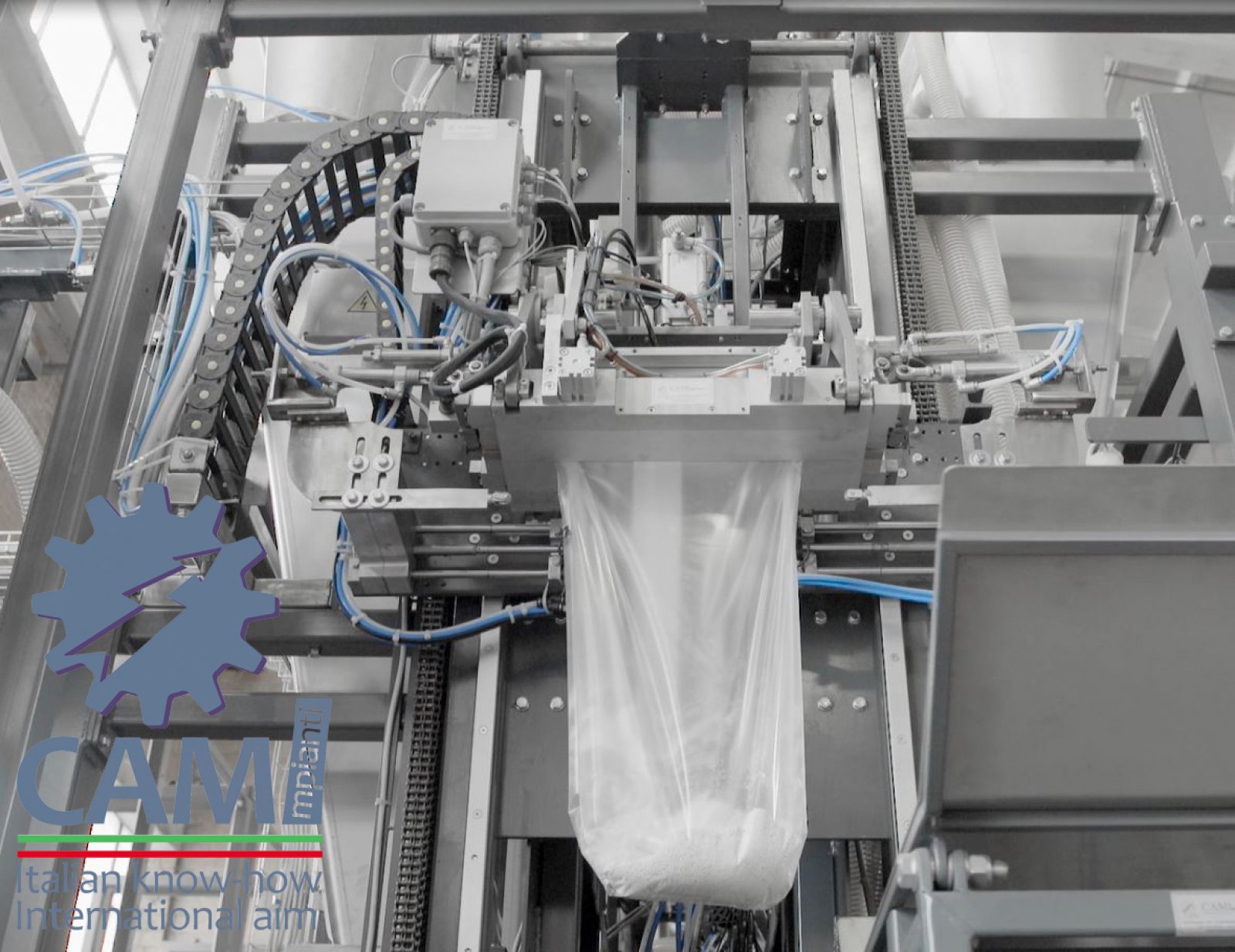

• Reduced dimensions

• High production capacity (1minute for each recipe)

• Simultaneous preparation of different compounds

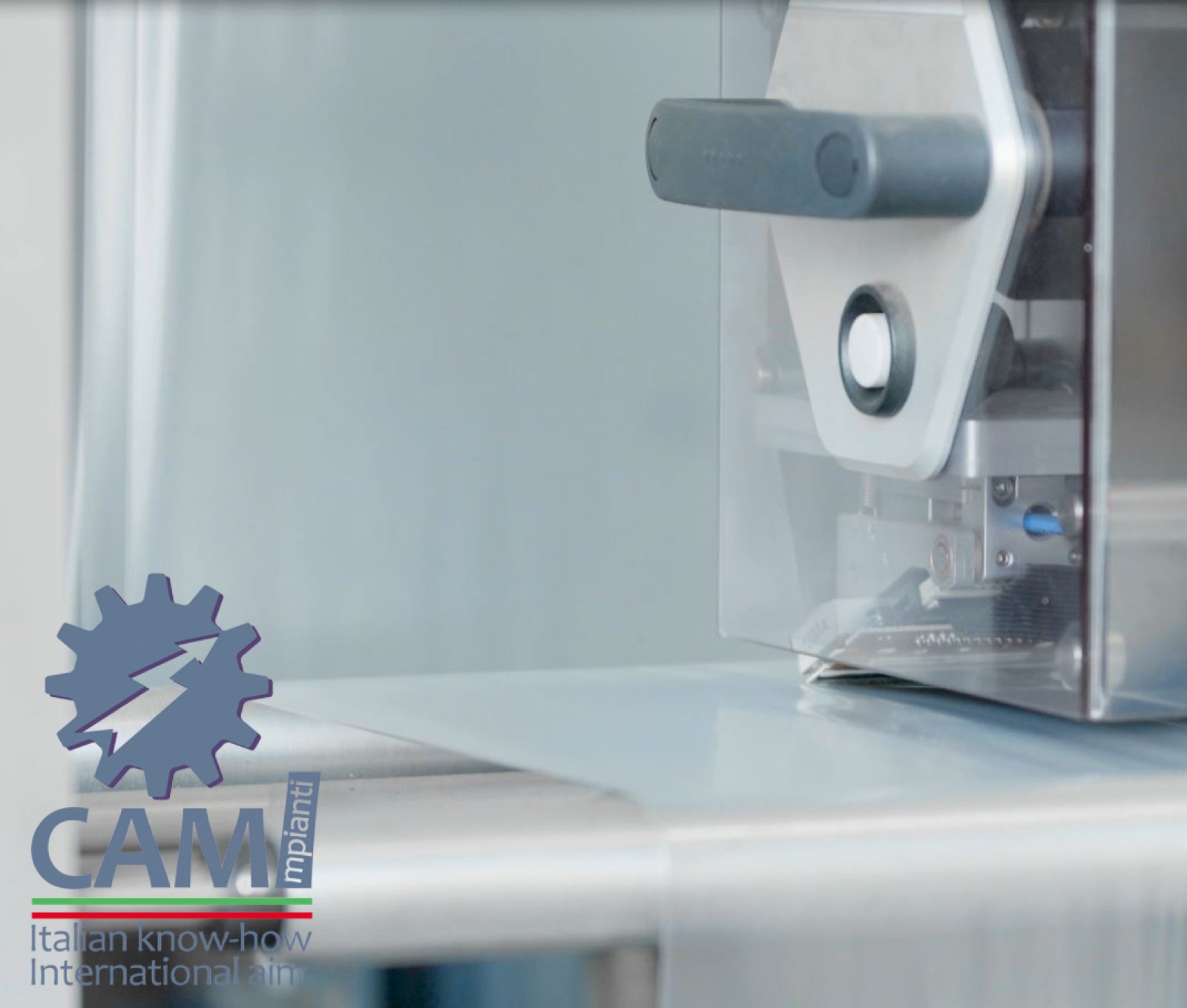

• Dosing accuracy

• Quality processing

• Machine modularity for possible future plant extension

• High product storage capacity (up to 300 liters)

• One operator machine

Main handled products:

• Benzoic acid

• Stearic acid

• Polyethylene wax

• Proton flux 16 wax

• Mbt

• Calcium oxide

• Titanium oxide

• Active zinc oxide

• Green zinc oxide

• Iron oxide

• Paraffin B

• Peg

• Permanax 6PPD

• Santogard PVI

• Coumarone resin

• Stearin

• Struktol SU 109

• Oiled sulfur

• Cbs

• Wax

• Titanium dioxide

• Calcium carbonate

• precipitated calcium carbonate

• pigments

• copolymers

• dicyandiamide

• hexamine

• calcium hydroxide

• zinc oxide

• polymers

• silica

• calcium stearate

• zinc stearate

• TMTM