Plastic

Plastic Industry

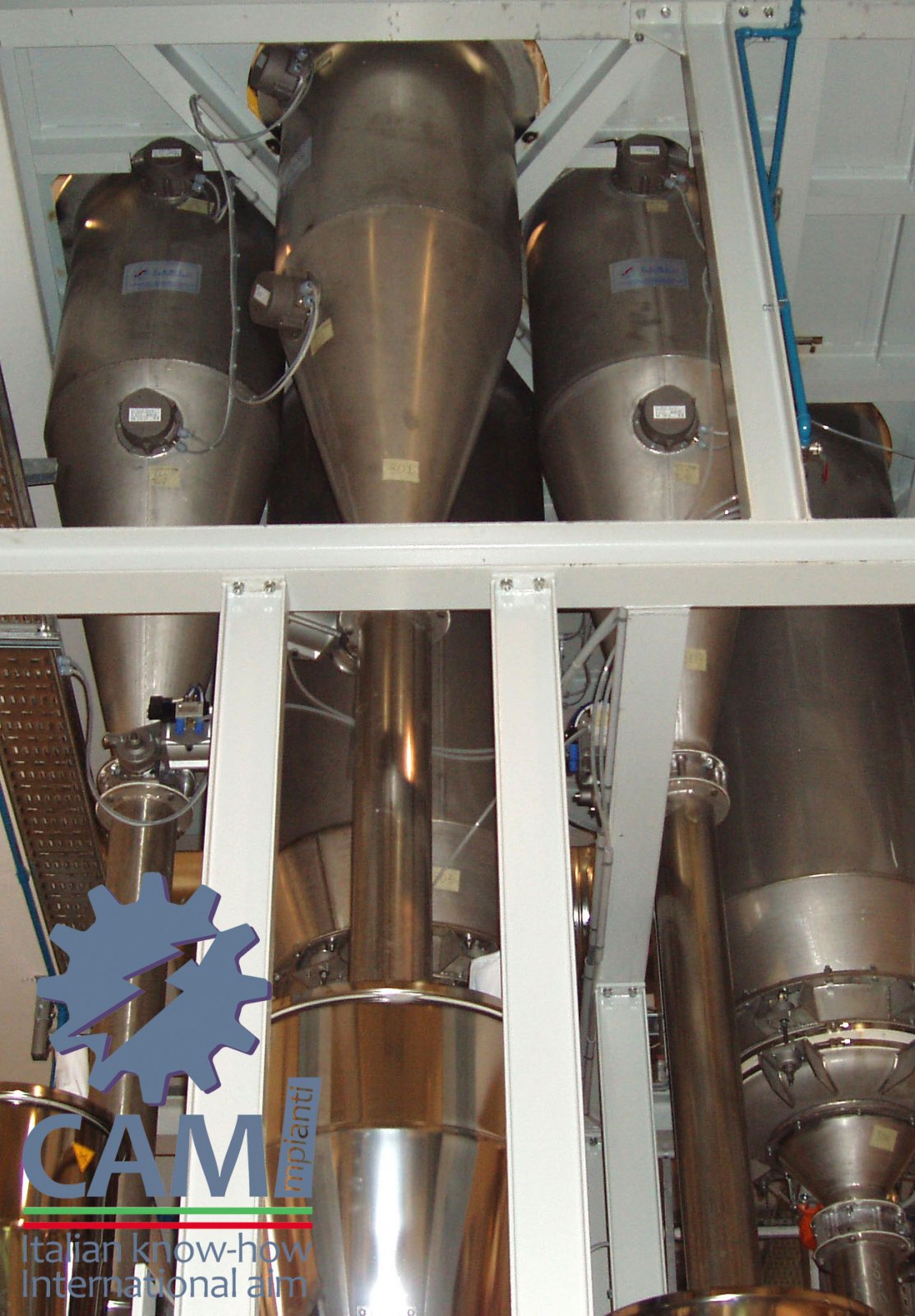

Producing fine chemicals requires an advanced technology able to preserve the materials properties and keep a high hygiene level while processing. According to the end-product recipe you wish, the plant solutions need to guarantee cleanliness and the possibility to check the line for inspection during production shifts. Furthermore, chemical.

materials are often fragile and need to be handled by systems able to keep the product integrity until its final destination.

CAMImpianti is a leader company in handling bulk materials both in powder and in granules and boasts a well-established experience in the manufacture of turnkey plants for the chemical industry. Our systems are equipped with easy-to-inspect machines and are planned to guarantee high-standard internal cleaning and allow production shifts according to the customer’s needs.

Our plants include systems for collecting bulk material into silos, big-bags or sacks, transport systems from storage, metering and mixing plants up to process machinery.

We gained experience in the following lines of production:

• semi-finished products for the refinement of oil products

• technical papers

• premixers for clutch components

• semi-finished products for the textile industry

• semi-finished products for the ceramic industry

• semi-finished products for the cosmetic industry

• premixers for construction industry.

With the introduction of the ATEX directive, old plants and new ones have been subject to the respect of the safety norms: CAMImpianti strictly cooperates with the leading manufacturers of explosion safety systems or explosion insulation ones studying each time the best solution for the customer.

Most handled products :

• vinyl acetate

• alumina

• atps

• titanium dioxide

• acetylacetonate calclium

• calcium carbonate

• precipitated calcium carbonate

• wax

• pigments

• copolymers

• dicyandiamide

• hexamine

• fiberglass

• calcium hydroxide

• glycerin monostearate

• polymers

• pvc

• silica

• calcium stearate

• zinc stearate