- Home

- BLOG: NOT FOUND

- Rotary valves: functioning and types

Rotary valves: functioning and types

In the previous articles we have focused on the types of transport describing their operation both in the dilute phase and in the dense phase. We also touched, in a marginal way, the subject of rotary valves. Precisely the latter are the protagonists of this article. We will see how they are made and which versions are most appropriate to choose to optimize the transport of the products of your production cycle.

The rotary valves are mainly used for the pneumatic conveying of powdered or granular products.

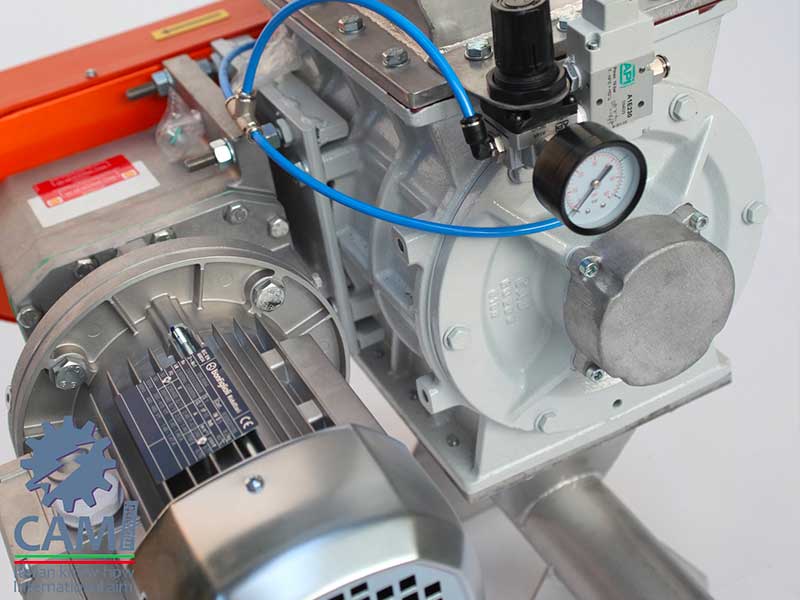

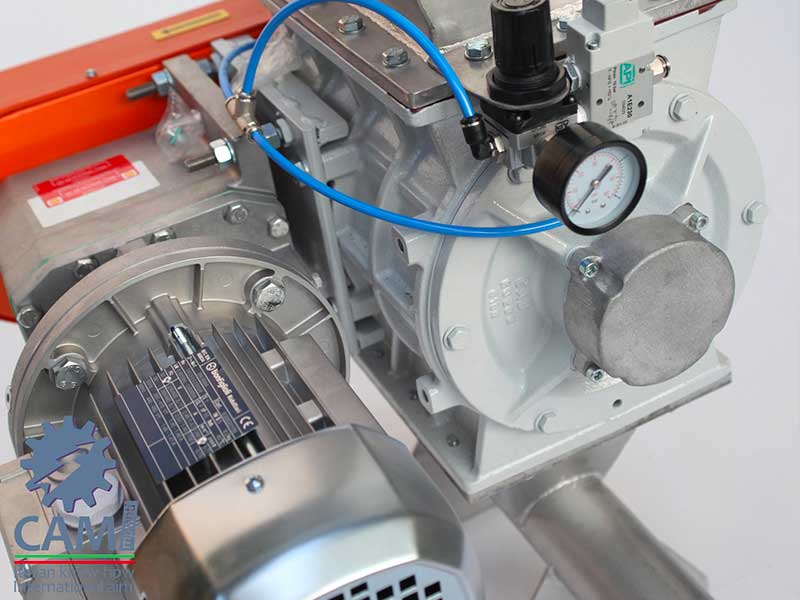

They consist of two main components:

• Machine body (built in painted, nickel-plated or chromed cast iron or in AISI316)

• Rotor (built in painted carbon steel, in stainless steel AISI304 or AISI316).

The rotary valves are used as:

- Sealing elements to allow the passage of solid products between two environments at different pressure

- Volumetric dosers

The star-shaped rotor, equipped with six or more blades depending on the size of the valve, allows this barrier function.

Rotary valves: versions and functioning

The rotary valves can be of two types or versions:

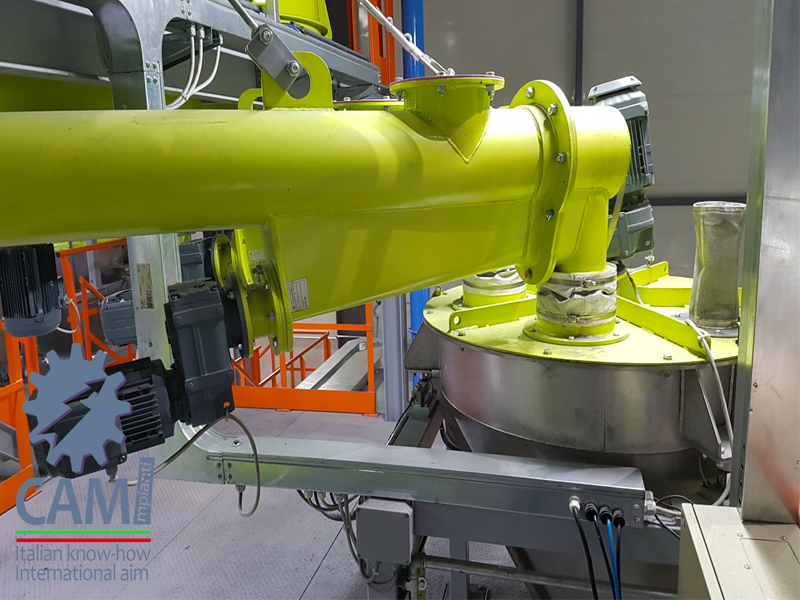

• RD or product flow crossed: unload the product from the upper part to the lower part of the machine body.

• RF or air flow crossed: they are used to introduce the product directly into the transport duct, the transport air passes, in fact, inside the machine body, emptying it of the product being discharged.

After this brief distinction, it is therefore easy to understand that the main function of rotary valves is precisely to separate two environments:

- from an accumulation such as silos, big-bags unloading stations or bags emptying hoppers to a pipeline whether under pressure or suction;

- from a cyclon-filter to extract the exhaust dust at ambient pressure;

- by a cyclon-filter which in turn feeds a transport line (typically the intermediate filter that divides a mixed suction / discharge system).

Types and components of the rotary valves

It is clear that according to the applications and, above all, the transported products, not only the construction material changes but also the shape of the rotor.

The rotor can in fact consist of:

- blades machined at 90 ° when transporting simple powders;

- beveled blades for granular products, to which one or two toothed blades can be added to avoid product fouling on the case;

- application of strips in harmonic steel or anti-abrasive rubber;

- rotors closed laterally when the transport involves abrasive products or for transport in dense phase with rotary valve.

In addition to the shape of the rotor, the valve body can also undergo changes: for example, in applications at high temperatures, spaced supports are used to prevent the bearings from being installed directly on the valve body, thereby increasing the temperature in a dangerous way.

Finally, in special applications it is possible to install a quick detachment system of the rotor to allow its control and cleaning: this application consists of a frame where the valve rests and completed by two tubes that act as a guide for both extraction and for reassembly.

Efficent conveying systems: choose CAMImpianti

To understand which transport system is best suited to your production cycle and which are the most performing components, such as rotary valves, we always recommend that you rely on the skill of professionals.

Relying on our decades of experience, we will be able to recommend the best solution for your needs, with the aim of making production systems more efficient. Contact us at any time.

Blog

Rotary valves: functioning and types

In the previous articles we have focused on the types of transport describing their operation both in the dilute phase and in...

Importance of conveying machines in industrial processes

Pneumatic Conveying systems The quality of the machines used for conveying of the raw materials, semi-finished products and ...

Microdosing systems

Industrial machines for dosage When we are talking about dosing related to industrial machines, it is very important to know...

Mass feeder dosing systems

Industrial Machines for dosing system The Industrial Machines’ business is become more and more perfect during the tim...