- Home

- BLOG: NOT FOUND

- Mass feeder dosing systems

Mass feeder dosing systems

Industrial Machines for dosing system

The Industrial Machines’ business is become more and more perfect during the time, by facing the specific needs of the customers. The Industrial Machines are utilizing for different activities as transportation, selection and dosing; the industrial machines are utilizing for different activities as transportation, selection and dosing... Each activity is important if made with the major precision as possible.In this article we are going to talk about the dosing systems: mass feeder dosing system.

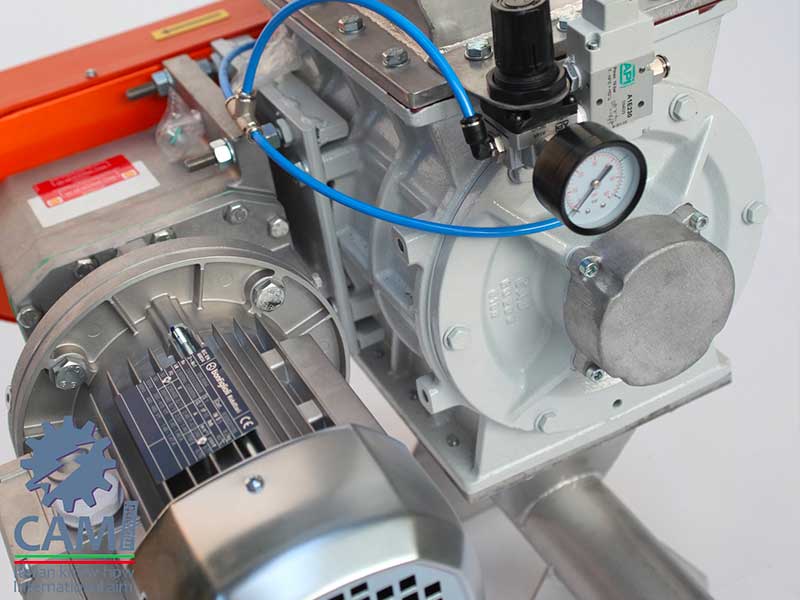

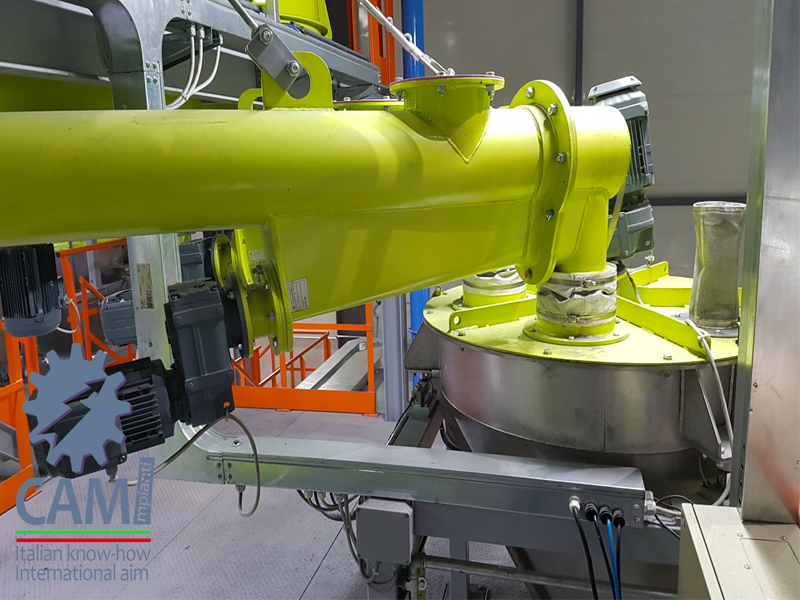

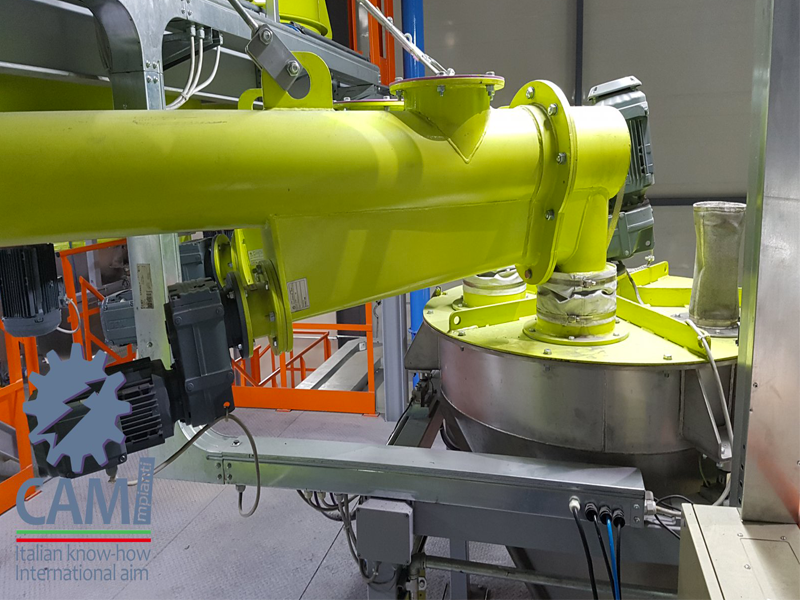

In the processing’s plants, the raw material handling’s step it is very important, for both transport and dosing phase as well. For example we can talk about butterfly valves, vibrating channels, screw conveyors transporters, and many more machineries for dosing.

Which are the dosing industrial machines

The caring and the ripetitiveness of the dosing systems, are the features of our Camimpianti’s Plants; this is why during the designing phase we are giving the most attention to this aspect.It is not existing just only one dosing method, but each of it has own peculiarity and specific system.

Depending on the application required, are existing two different ways of dosing system:

- In addition;

- In substraction;

In addition

The dosing systems “in addition”, are working in increasing of weight: several dosing systems (screw conveyors or vibrating channels) arrive on a scale, extracting the raw material from the daily tanks or from silos and loading, one by one, the products inside the scale. The products can also be weighed on the balance by a pneumatic in diluted phase conveying system.In substraction

For dosing system “in subtraction” it is intended that is working in decrease of weight: each product is on a single scale which will dose the product inside a tank or inside a processing machine.The differences between the two type of industrial machines systems

Let’s now evaluate the main differences of the two industrial machine systems. The evaluation is technical and it is based on the fact that it is not possible to speak about real pros and cons, considering that depending on the processing required, what for someone can be a pro per other turns out to be a cons.The main differences of the two solutions are that, with the first system, the plant costs are reduced but there are higher dosage tolerances as automation will have to manage the product "falling" on the scale.

On the contrary, the second method is more precise inasmuch the dosing system immediately feels the amount of product extracted. In addition, in the second case, it is possible to dose several products simultaneously.

Dosing machine for any need

The CamImpianti’s dosing system are designing and built by follow the specific needs required: in some cases (for example when it is necessary to dose big quantities of product or when we have raw materials with really high specific weights), it is used a double screw conveyor, the biggest one inside for dosing the product’s large quantity and the smallest one to allow to make a more accurate fine dosage.

Blog

Rotary valves: functioning and types

In the previous articles we have focused on the types of transport describing their operation both in the dilute phase and in...

Importance of conveying machines in industrial processes

Pneumatic Conveying systems The quality of the machines used for conveying of the raw materials, semi-finished products and ...

Microdosing systems

Industrial machines for dosage When we are talking about dosing related to industrial machines, it is very important to know...

Mass feeder dosing systems

Industrial Machines for dosing system The Industrial Machines’ business is become more and more perfect during the tim...