- Home

- BLOG: NOT FOUND

- Importance of conveying machines in industrial processes

Importance of conveying machines in industrial processes

Pneumatic Conveying systems

The quality of the machines used for conveying of the raw materials, semi-finished products and finished products is very important for the integrity of the products themselves and therefore for the economy and efficiency of the entire production process.Which Criteria need to be follow for choosing the correct conveying system?

It must be said that, with the fast progress of the technologies, the choice of the conveying system to be applied to its own production has also changed considerably over the years.

Generally we can confirm that there are two types of pneumatic conveying systems:

- Diluted phase: high speed (at least 18-19 m/s at the start according to the products transported) and low pressure (maximum target 0.8 bar in pressure) which we will talk about in this Blog

- Dense phase: low speed (maximum 8 m/s) high pressure (maximum 4 bar)

In an important book of the end of the 80’s, about the conveying systems, it was indicated as a fundumental rule for the choice of the conveying system, the follow:

- In pressure: to transport from one point to multiple points

- In suction: to transport from multiple points to a one point

- Suction-pressing : to transport from multiple points to many points

Indeed the correct transport is depending even from the combination of:

- Type of material to transport

- Distance of the transport

- Flow rate required

A very abrasive product, for example, is normally conveyed by dense phase because the low speed reduces the wear of the pipes but, for low flow rates and short stretches, a diluted phase transport could also be used; even a blended product that has high diversity of specific weights of the raw materials which it is composed, therefore subject to segregation, is normally transported in dense phase but, for short stretches, could also be transported in diluted phase.

Conveying systems in diluted phase

The conveying systems in diluted phase can be, as above indicated:- In Pressure: Normally used with not sticky products, easy to carry. This system at an economic level is certainly the most worth it of the systems, as the management of more arrival points involves the installation of a few simple machines.

- In suction: normally used for products also sticky, harmful or precious because the possible loss of a pipe does not allow the escape of dust. This system is definitely more expensive but more flexible and "safe" for the product.

- Suction-pressing: normally used for long stretches or in the case of thermic treatment of the transport air. For example, for the conveying of low flux products, a first part of the intake sampling can be used and, subsequently, resumed with the pressing part complete with heat treatment of the air to lower the temperature.

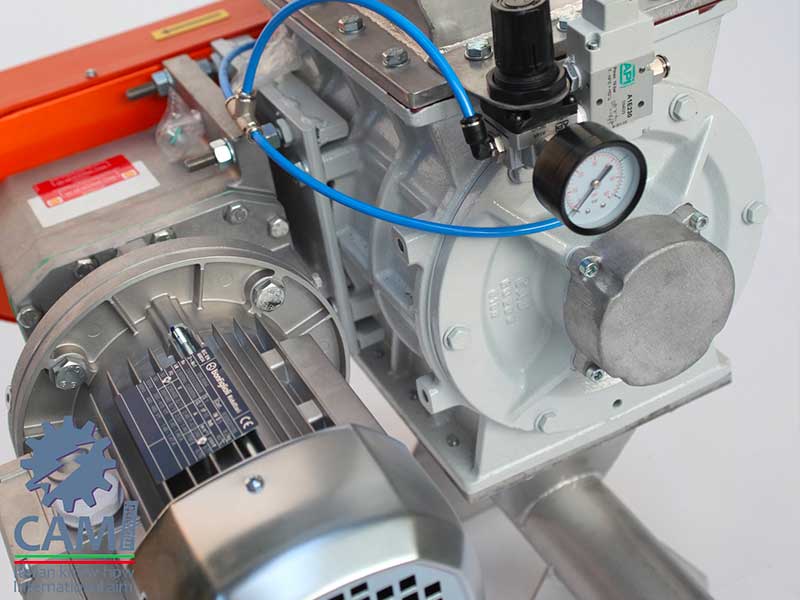

The transport lines in the diluted phase need to be fed with a dosing device: in pressure, rotary valves are used which, in addition to dosing the product, also have the function of a barrier on the line in order not to lose the air; in suction screw conveyors complete with butterfly valves are used to close the line.

The conveying gas normally used is air, while in special cases, for example for explosive products, closed circuits in nitrogen are used to inertize the line. Depending on the size of the line, the gas is sucked or compressed with lobe compressors, side duct compressors or fans.

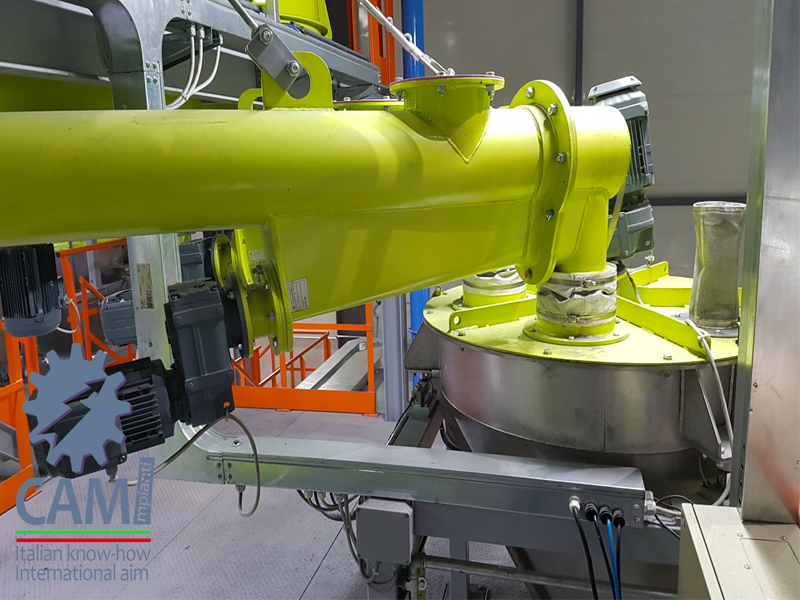

In the case of multiple points of destination, the line is diverted with drum diverter valves or flap type; also in this case the use depends on the products treated and the pressures involved.

On the arrival points are placed filters dust collectors or cyclones separators which we will talk in detail in the coming blogs.

In essence, therefore, Camimpianti conveying systems are created to meet all needs, always keeping up with the technological advancement. At this link an overview of all the machines available and their detailed descriptions to choose the transport system best suited to your production cycle.

Blog

Rotary valves: functioning and types

In the previous articles we have focused on the types of transport describing their operation both in the dilute phase and in...

Importance of conveying machines in industrial processes

Pneumatic Conveying systems The quality of the machines used for conveying of the raw materials, semi-finished products and ...

Microdosing systems

Industrial machines for dosage When we are talking about dosing related to industrial machines, it is very important to know...

Mass feeder dosing systems

Industrial Machines for dosing system The Industrial Machines’ business is become more and more perfect during the tim...