- Home

- BLOG: NOT FOUND

- Microdosing systems

Microdosing systems

Industrial machines for dosage

When we are talking about dosing related to industrial machines, it is very important to know if we are referring to macro or micro dosage. In this article we are specifically touching the micro dosing system subgroup.The micro dosing systems in industrial plants have to guarantee a repeatability’s capability of the weighed by maintain the same level of precision. Obviously as more the weighed maintains a good precision as more the machine is qualitatively interesting.

The sizing and the feeding of the dosing machine components are the main feature to obtain the desired results.

Microdosing system, let’s analyze the detail

In food, rubber and chemical industries and more in general in industries where industrial machines are deployed linked to the dosing, microdosage is normally understood as dosages ranging from a few grams up to 4/5kg for each production cycle.

Type of microdosing systems

The microdosing system can be on two different type:- single point of dosage

- multiple points of dosage

Single point microdosing system

Single point microdosing system is recognizable because it has an only one point where the dosing is made; the dosing is usually made in subtraction by positioning the dosing machinery on loading cells and the related loading hopper.

Multiple point microdosing system

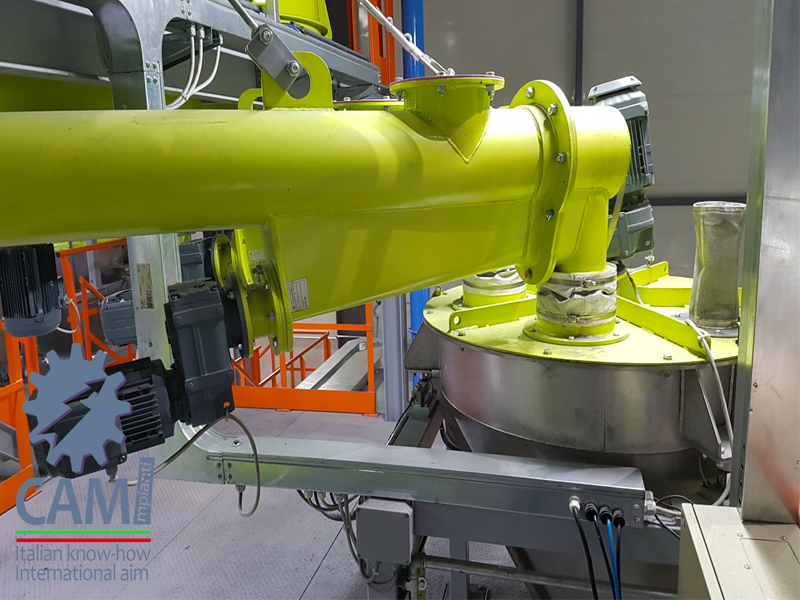

The multiple points microdosing system presents many microdosing mechanical points that are feeding a scale or a tank. In this case CAMImpianti has designed the ABC Machine - Automatic Batch Composer.

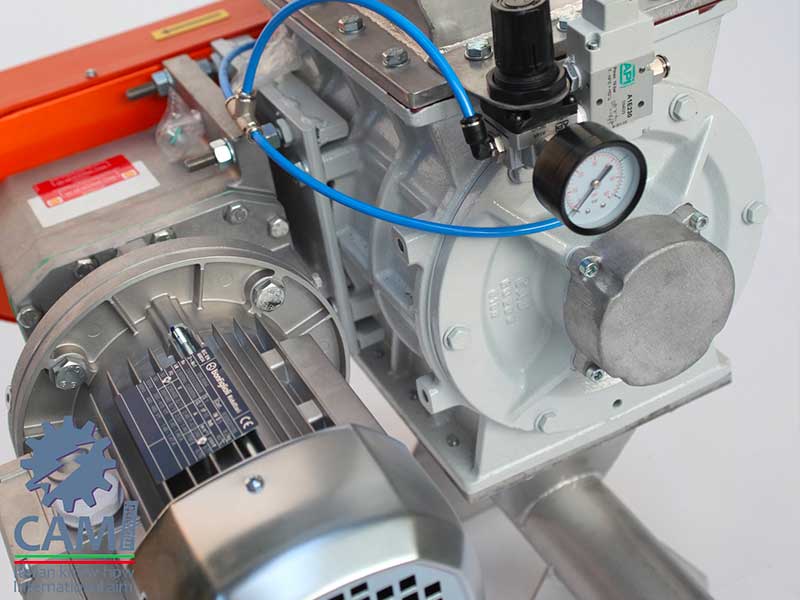

Microbatchers and treated products

Depending on the products treated, for example in case of sticky products or with little sliding, the microbatcher is completed by an internal shaker that facilitates the feeding of the extraction screw in a homogeneous way.In other cases where the minimum and maximum dosage ratio exceeds 1:10, in the timing cycle, are been studied solutions for the fast disassembly of the dosing component, without intervening on the control engine, so as to have higher ranges of dosing.

Industrial machines for microdosage

The CamImpianti’s microdosing systems are designing and built by follow the specific needs required.Regarding the dosing screw conveyor, this is realized in different ways:

- screw conveyor with shaft and auger

- screw conveyor with hollow auger

- spring screw conveyor

Depending on the fragility of the product, the dosing system can be realized by using vibrating channels.

Eventually, in some cases where it is necessary to utilize the Microdoser in multiple points of the Plant, the entire group is installed on a platform carried by a forklift complete with power batteries to reach the maximum flexibility.

CAMImpianti ABC System

More often CAMImpianti is proposing the ABC system, as above indicated, based on the specific needs of the market. This system produces predated bags of microcomponents. The machine starts from an EVA coil, it forms the bags that, inserted in a container, move under the microbatchers.The bags are identified with barcode to allow the tracking of it, inside the Plant’s supervision system. The machine is completed with a manual weighing station placed on board and possibly of a rotating warehouse; this allows to put the component to be dosed in front of the operator. For the most commonly used components, a big-bag emptying system can be installed.

Click HERE to see a video about the "small chemicals" dosing system for the rubber industry built and certified by CAMIMPIANTI srl, consisting of 36 automatic mechanical components and an automatic bagging system.

Blog

Rotary valves: functioning and types

In the previous articles we have focused on the types of transport describing their operation both in the dilute phase and in...

Importance of conveying machines in industrial processes

Pneumatic Conveying systems The quality of the machines used for conveying of the raw materials, semi-finished products and ...

Microdosing systems

Industrial machines for dosage When we are talking about dosing related to industrial machines, it is very important to know...

Mass feeder dosing systems

Industrial Machines for dosing system The Industrial Machines’ business is become more and more perfect during the tim...